At Dinex, we are extending our emissions expertise into several of

Large engine applications for large engine platforms: stationary

gensets, marine, industrial power generation, and rail. And at the

heart of this expansion lies our modern, automated CHP-SiC facility

in Changzhou, China.

Developed in close collaboration with Dinex’s global R&D team, every large engine solution from Dinex China begins with simulation-driven development aligned to high performance targets.

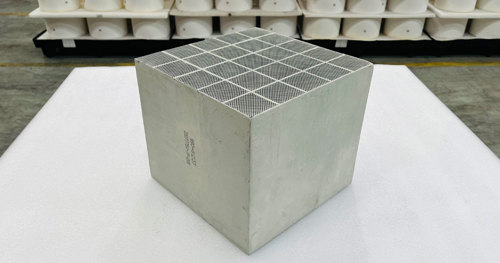

From the lab to the field, our DPF modules are tested and validated at our own facilities before entering serial production in China. Each module passes through a fully integrated production flow – from segment extrusion, sintering and assembling to substrate, coating and final metal canning – all under one roof.

Our DPF modules are engineered to meet or exceed the world’s toughest emission standards: Stage V, Tier 4 and BImSchG.

Our latest generation of Diesel Particulate Filter (DPF) modules is built on a proprietary reaction-formed, highporous SiC substrate.

These modules are purpose-built for:

Perfect for OEMs seeking both performance and compliance – without compromise.

Dinex’s Changzhou facility is not just a production site – it leverages China’s unique strengths to deliver unmatched value for customers worldwide.

Whether integrating our fully extruded SCR bricks, custom substrates, or cassette-based DPF systems, OEMs gain access to:

As a trusted OEM partner, Dinex delivers tailored emission control components with unmatched flexibility – backed by 40+ years of global experience and localized execution across Europe, the US, and Asia.

Get more insights on advanced aftertreatment solutions for large engines applications here.

Here you have the opportunity to download the article